What Is DFM ?

DFM

stands for Design for Manufacturability, Having knowledge of DFM could resolves

the queries like what are the loopholes and complexities of the design? How to

simplify them? Is the design even manufacturable? Or can it be designed to get it

done in an optimized cost?

A

properly-executed DFM looks like an amalgamation of all the stakeholders including

designers, engineers, contract manufacturers, and material suppliers.

DFM

ensures that the design is optimized and does not have unnecessary cost

embedded in it. Therefore, DFM is knowing the best design to fit your

electronics in terms of both cost and complexity.

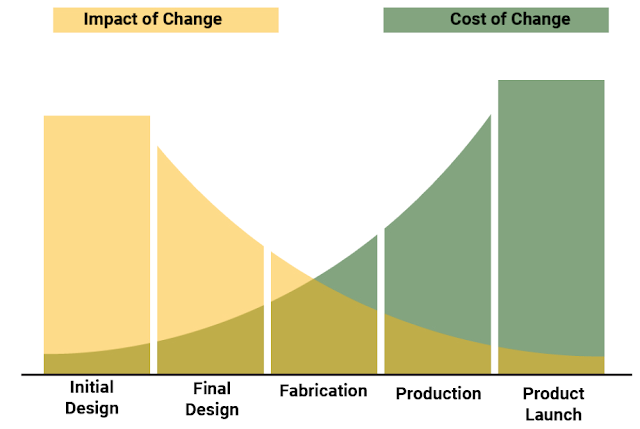

The

image above is a real time rendition of why we need DFM. The simultaneous

Impact

and cost of a change in design as we go into the process actually defines the

purpose of DFM in the PCB industry.

It

is a critical manufacturing tooling design and process development step before

making a new product. Coming together of all stakeholders early in the design

process is easier if you’re developing a new product. But you must keep this in

mind that even with an established product, challenging the original design is

a

Necessary

element of a thorough DFM. Too often, mistakes in the design are repeated by

replicating a previous design. Question every aspect of your design.

If

done well, DFM will assure quality, reliability and productivity through the

life of the product. DFM is more manufacturing dependent for more

complex

Technology. It takes time but

can save you in total cost.

No comments