Troubleshooting of Reflow Soldering Defect

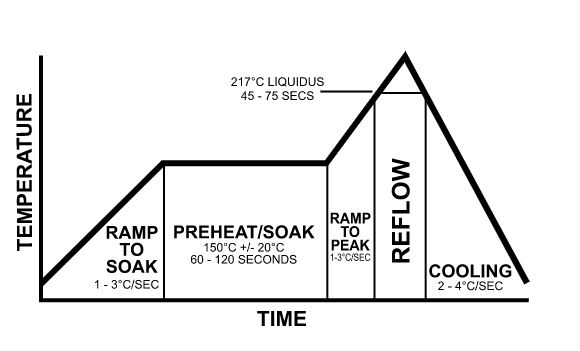

Reflow Soldering is Very important Process in SMD (Surface Mount Device) Assembly. Reflow soldering in devided into diffrent zones and they are Preheating, soaking, Reflow and Cooling Zones. Solder particles melts at Temperture 183 ͒ C for leaded Process and 217 ͒ C for lead free process.

👉 Preheating Zone:

When the ramp up speed is too high at the preheating zone it will cause solder paste to slump

due to thermal agitation and induce defects such as bridging, solder balling, tombstoning, solder

beading, and micro-cracking on ceramic components. When these problems occur, an optimized

(or semi-optimized) reflow profile with a slower preheat ramp up rate is preferred.

👉Soaking Zone: If the temperature of the soaking zone increases it may cause poor wetting, solder

balling, voiding, components damage and PCB

delamination or charring.

👉Reflow Zone: If the Reflow temperature

is too low it may cause cold solder joints and poor wetting. However, if the Reflow peak temperature is

too high, it not only may cause damage to the PCB (warpage, delamination, and charring), but

also promotes defects such as tombstoning, solder beading, and voiding due . A high peak temperature also increases the duration time above the solder

alloy’s liquidus temperature (wetting time, timeover), which may cause dewetting and excessive

intermetallics formation.

👉Cooling Zone: If the cooling rate is too slow (>5° C/sec) it will not only cause excessive IMC (Inter-Metallic Compounds) formations, but also cause coarse grain structures and phase segregations in the solder alloys due

to the annealing effect which may raise reliability concerns. On the other hand, if the cooling rate

is too fast it may build up too much internal strain in the solder joints causing joint detachments

and shrinkage voids.

Some of the Reflow Soldering Defect and Possible Cause is Listed Below:

- Cracked Chip Capacitors: This problem arises due to Excessive rise rate in the preheat zone of the Reflow

- Solder Balls: The possible cause of this problem are Incomplete Drying before Reflow (Dryout section too cool and short duration), Excessive drying temperature (fluxes skin over) , Improper gas atmosphere (Nitrogen Vs Air ) .

- Cold Solder Joints: This Deffect occures due to Insufficient time over Reflow temperature.

- Solder not wet to leads: Due to Excessive drying time causig fluxes to deteriorate and Exceesive reflow temperature / time causing oxidation this problem occures.

- Solder not wet on pad: This Problem occures when lead is heating faster than board (Too much Air flow)

- Component / Board Burning: The exceess / Too high temperature of Reflow cause Component / Board Burning

- Tombstoning: There are two factors contributed to the tombstone phenomena: a) an unbalanced torque on two sides of the chip components due to the surface tension of the molten solder; b) an upward push by solvent vapors from flux or PCB during the reflow process. A fast ramp up rate during the reflow stage will aggravate the outgassing to increase the chance of tombstoning.

- Poor Wetting: The primary root cause of poor wetting is excessive oxidation of solder powder, component leads, and PCB pads prior to the reflow.

- Voiding: The root cause of the solder voiding is primarily due to the entrapment of flux during the reflow stage. Formation of solder voids increases with the oxidation level of both solder powder and the PCB pads.

What should be the average reflow time and temprature range for pcb contains QFP or BGA

ReplyDeleteAverage Reflow time will be approx 30-90 sec and temperature range depends on peak temperature of device and also whether the device is leaded or lead free.

Delete